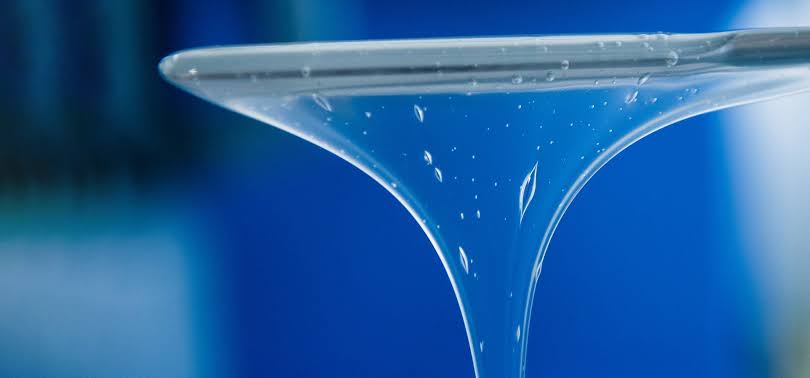

Medical silicone is a crucial material in the healthcare industry, especially for medical devices and implants. It has unique properties that make it suitable for use in contact with human tissues and fluids. Silicone is biocompatible, meaning it can be safely implanted into the body without causing adverse reactions or rejection. It is also inert, which means it does not react with other substances or corrode over time.

The cost of medical silicone is mainly due to its high degree of purity and quality requirements. Unlike industrial-grade silicone, medical-grade silicone must undergo strict regulations to ensure its safety for use in humans. The manufacturing process of medical silicone involves expensive testing methods such as gas chromatography-mass spectrometry (GC-MS) to detect any impurities that may cause harm to patients.

Moreover, there are significant costs associated with research and development of new medical devices made from silicone materials. Medical device manufacturers invest heavily in designing innovative products that meet the specific needs of patients while complying with regulatory standards set by authorities like the FDA (Food and Drug Administration). Ultimately, although expensive, investing in high-quality medical-grade silicone ensures patient safety and effective treatment outcomes.

Defining what medical silicone is and its uses

Medical silicone is a type of silicone that is specifically designed for medical purposes. It is used in various medical devices, implants, and prosthetics. This type of silicone is different from regular silicone due to its purity level and the absence of additives or impurities that could cause an adverse reaction in the patient’s body.

Medical-grade silicone sheet has unique properties such as biocompatibility, durability, and flexibility. As a result, it can be used in various applications such as breast implants, pacemakers, catheters, artificial joints, and other implantable devices. The material’s biocompatibility means that it does not react with the human body when implanted or inserted into it.

The production process for medical-grade silicone involves strict quality control measures to ensure the product meets regulatory standards. This process increases manufacturing costs significantly compared to regular silicone products. Moreover, since there are limited manufacturers of this specialized material globally which further drives up the cost of production. The high price tag for medical-grade silicones reflects their stringent manufacturing requirements and rigorous testing protocols required to meet health standards ensuring maximum safety for patients undergoing surgical procedures involving these materials.

The production process

One reason why medical silicone is expensive is because of the production process. It requires a high level of precision and quality control to ensure that the final product meets the strict standards set by regulatory bodies such as the FDA. The raw materials used in medical silicone production are also more expensive compared to other types of silicone.

The production process for medical silicone involves several steps, including mixing, curing, and molding. Each step requires specialized equipment and skilled technicians to ensure that the end product is free from defects or impurities. Additionally, since medical silicone products are often used in implantable devices or other critical applications, they must undergo rigorous testing and validation before they can be approved for use.

Overall, while the production process for medical silicone may be more complex and costly compared to other types of silicone, it is necessary to ensure that these products meet the highest standards of safety and effectiveness for patients.

Conclusion:

In conclusion, the high cost of medical silicone can be attributed to several factors. Firstly, it is a specialized material that requires careful processing and manufacturing procedures to ensure its safety and efficacy for medical use. This involves adhering to strict quality control standards and using advanced equipment and technologies, which adds to the production costs.

Additionally, the demand for medical-grade silicone is relatively low compared to other materials used in medical devices such as plastic or metal. This means that the economies of scale are not achieved, making it more expensive per unit than other materials.

Lastly, there are regulatory requirements that need to be met before any medical device made from silicone can be sold on the market. These requirements include rigorous testing and certification processes that also add up to the overall cost of producing medical-grade silicone products.

In spite of these factors contributing to its high cost, medical-grade silicone remains a vital material in many life-saving devices such as pacemakers, breast implants, catheters and respiratory masks. Its unique properties allow it to withstand extreme conditions while remaining safe for prolonged use inside the human body – making it an essential component in modern medicine today.

SUCONVEY MEDICAL SILICONE RUBBER SHEETING